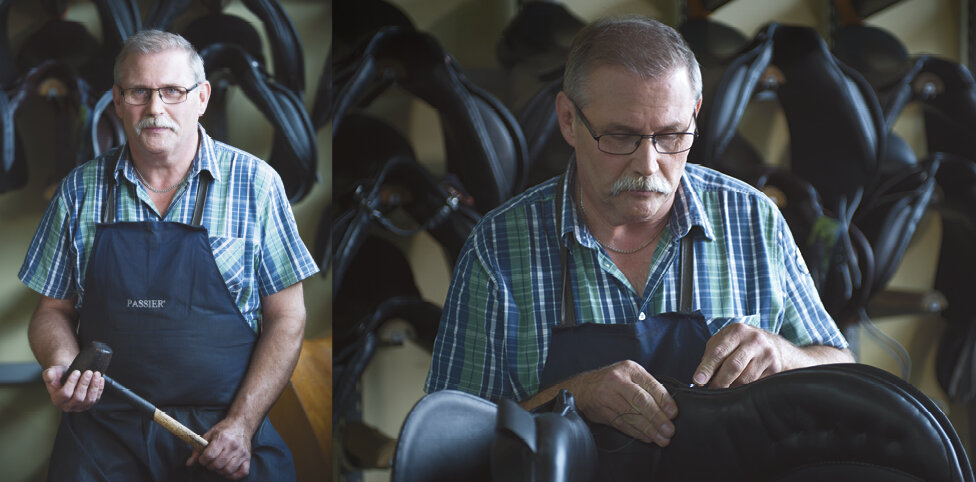

I am Proud of the Results of My Work!

In the early 1970s, my brother-in-law, who was already working for Passier, asked me whether I would also be interested in working for the company. I was 17 years old and said “yes” immediately. At the start I was involved in making the Century Saddle, which was a saddle for the American market. My brother-in-law showed me all the necessary production steps. At that time, Mr. Passier and Mr. Kannemeier Senior were still at the company. They used to come into the workshop every morning and say “good morning” to all of us.

You Can Hear Whether a Nail is Positioned Correctly

Later, I sewed the large saddle flaps onto saddles and attached the panels. Attaching the panels underneath the saddle was the most difficult task. It also required a considerable amount of physical effort. One morning, I remember, I was in the process of nailing down the saddle welt when Mr. Passier came along. I was busy hammering the nail and Mr. Passier stopped and said “Mr. Manthey, the nail isn’t in properly. It hasn’t gone into the wood”. And what could I say? He was absolutely right! And he had noticed this simply on his way past, although he was about 70 years old at the time! Afterwards, I tried it out myself and discovered that it really is possible to hear whether a nail is positioned correctly! He still had excellent hearing, but that was not all – if anything was not quite right with a saddle, he always noticed immediately.

You've Got to Get the Hang of Things

Meanwhile my work has become easier – I have developed certain routines. Once you’ve got the hang of something, it goes really well. I’m not the type to work in an office and stitching snaffle bridles would be far too fiddly for me! I’ve been doing repairs for 20 years now and thoroughly enjoy the variety: re-flocking panels, adjusting gullet plates, seats, gusset leather, billets … Every day is different. I work on three to six saddles a day, depending on how much work each saddle requires.

Clearly in a Class of Its Own!

We had a saddle in for repair once which was 50 years old. But no-one would have guessed. It was still in great condition! When you look at a saddle like that and see how perfect everything still is, it makes you feel really proud. Even though I didn’t actually make it myself – because it dated back to before my time. Quite clearly in a class of its own! The leather had also been cared for very well. It was really soft and the grain was still recognizable. So, I then fit it with a couple of new billets. When we receive saddles for repair these days, they are cleaner than they used to be. I can still remember that saddles were often quite dirty and smelt strongly of horses. In the past, saddles were also tumbled, meaning the leather was turned in and the thigh support was tucked inside. Nowadays, however, customers don’t require that anymore. Another thing that has changed is that the supports are becoming increasingly bigger and the seat linings softer. Saddle seats used to be as hard as a rock.

I Will Certainly Miss Passier

The best aspect of my job is being able to see what I produce. And the result is really something to be proud of because people get a lot of pleasure from our saddles. I enjoy working at Passier. This March I will retire after 45 ½ years. Definitely something to look foreward to! The knowledge I gained over the years I have already passed on to my younger colleagues. I know that they will do a great job! But nevertheless I will certainly miss Passier …

Dieter Manthey, Passier member of staff since 1975